Description

What is a spa boiler?

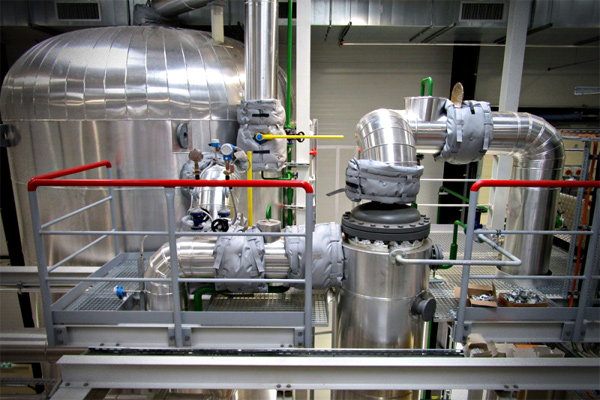

Today, the use of motorhomes and central heating systems in general, such as hot water boilers, is very common, because these systems are easy to implement, have high efficiency, and are in the cost-effective category. It is very important to note that heating systems and motorhomes use a hot water boiler in their structure, which also has a direct and significant effect on the performance of the heating system. Given that today everyone is looking to use the best and most cost-effective equipment, it is necessary to introduce you to the spa boiler a little more. So join us in the continuation of this article to examine the types of spa boilers and the different applications of each of these boilers.

Hot water boiler

Spa cauldron

A hot water boiler is a very practical device that can, with the help of its special structure, bring water to the desired temperature of the system in the best possible way. To do this, the boiler transfers the heat energy from the fuel to its own heater and heats the water. Hot water also returns to the system after use and cooling for reheating.

Application of spa boiler

The most common use of hot water boilers is for heating and heating systems of houses. However, the applications of hot water boilers are not limited to homes and home heating systems and have many applications in industry, so that in many factories and even power plants we see the use of these hot water boilers.

Hot water boiler

Different components of the spa boiler

In order to get acquainted with the correct operation of this boiler, it is necessary to first get more and better acquainted with the various structures and components. The main components of a spa boiler are:

1. Burner and combustion chamber: These parts supply the heat required by our heating system and their performance has a direct impact on energy savings.

۲. Body: The main chassis and the cover of the hot water boiler are called the body. Depending on the type of application of the boiler, one should choose between two types of cast iron and steel.

3. Control section: The task of controlling the boiler temperature and the operation of the burner is the responsibility of this section.

4. Deaerator: Deaerator is responsible for quality control and purification of water entering the hot water boiler system and also plays an important role in reducing scale and corrosion of various components of the system. Using the right deaerator can reduce the maintenance and repair costs in our system to a very high level.

5. Fire pipes: These are steel or cast iron pipes with fire and smoke in them.

6. Manhole and handhole valves: These valves are installed for easy inspection and inspection of the system.

7. Safety and drain valves: They are installed for better system performance and prevention of system damage due to high pressure.

.

8. Economizer: The economizer, as its name implies, is built and designed to make the system more economical. This part of the system acts as a heat exchanger and preheats the feed water using the heat output and waste.

9. Tube Sheet: The chamber in which the fire pipes are placed.

10. Fans and blowers of the system: The fan is used to move the gases and fluids of the system.

۱۱. Heat exchange section: It is a plate in which the thermal conductivity is at its best and the temperature transfer between water and the burner is done on it.

۱۲. Precision Adjustment Tool: This part of the system executes operator commands and manual commands as accurately as possible.

13. Fuel transfer system: The task of this section is to transfer fuel from the tank and tank to the burner.

۱۴. Water tank: The tank is used to store the water needed by the boiler.

۱۵. Barometer and thermometer: Used to control the pressure and temperature of the boiler at the moment.

Hot water boiler

Types of spa boilers

In terms of boiler material, hot water boilers can be divided into two parts: cast iron and steel:

Cast iron hot water boilers: These boilers are made of cast iron blades made by cast iron casting techniques. The heat capacity of these boilers is directly related to the number of blades.

Steel hot water boilers: Refractory and heat resistant steel are the main materials for making these boilers. The efficiency of these boilers is very high, but their high weight makes them a little difficult to implement.

General comparison of cast iron and steel boilers

Cast iron boilers play the role of French wrenches in heating systems and can be used in a wide range of systems. Cast iron boilers are much easier to move than steel boilers. On the other hand, cast iron boilers have an acceptable resistance to corrosion and rust. The good price of these boilers has also made their use very common.

If you ask experienced people about these two, they will undoubtedly tell you that moving cast iron boilers is much easier and more convenient than steel boilers. Because steel boilers are heavier and bulkier and are mostly used in large industrial systems. Their working efficiency is very high and their heat capacity is also very good. Steel hot water boilers have a longer life than cast iron ones and are more reliable for large and high pressure systems.

In cast iron boilers, if the blades are damaged, it is possible to replace that blade, but you should also keep in mind that cast iron boilers are not suitable for cold and mountainous areas due to the possibility of heat shocks and their efficiency. In such conditions it is greatly reduced.

Ideal place to install a spa boiler

The installation location of the hot water boiler should be perfectly level so that no additional force enters the pump and burner. If the hot water boiler is not level, in the long run we will see broken pipes and damaged connections. In addition to the level of the boiler should be at least 10 cm from the floor. Proper airflow is also essential for better combustion operations

.

دیگ آبگرم

What factors should be considered to choose the right boiler and burner?

Before choosing a boiler and burner, it is better to carefully examine these factors to avoid possible troubles:

– Useful life

– Maximum heat capacity and its ability to change

– The temperature of the water returned to the system, which indicates the efficiency of the system

– Initial cost of the plan

– The cost of energy consumption courses

– maintenance cost

– Reliability

– Type and calorific value of fuel

– Heat efficiency of the burner

– Altitude of the place of use of sea level

– Appearance and amount of pressure drop

Conclusion

In order to choose the right boiler, it is better to increase your knowledge, and also get help from an expert to minimize the risk of your work. Do not forget that some costs in the system can prevent more and heavier costs in the future, so it is better to always go for the best technologies and the most up-to-date equipment. Finally, we hope you have taken advantage of this article

.

Reviews

There are no reviews yet.